Arduino ESP32-CAM for video stream notebook

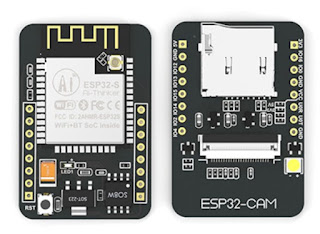

Preface Recently, I acquired an ESP32-CAM Wi-Fi + Bluetooth + OV2640 camera module. My first intent was to learn how to use new Arduino ESP32 compatible modules. Then, I quickly found out with ESP3D that I could use ESP32-CAM to monitor and control my Ender 3 Pro 3D printer remotely, what a bonus! This is my personal notebook and you are welcome to follow along and hope it might actually help! Goal for this post Config ESP32-CAM to use it as a web server to stream videos. Long term goal is to use ESP32-CAM and ESP3D to make a 3D printer remote monitoring device. ESP32-CAM Spec ESP32 32bit dual core 600 DIMPS 520KB SRAM + 4MB PSRAM I/O: UART, SPI, I2C, PWM MicroSD: Up to 4GB Baud Rate: Default 115200 bps Photo format: JPEG( OV2640 only), BMP, GRAYSCALE Wi-Fi: 802.11 b/g/n/d/e/i/k/r Bluetooth: V4.2 BR/EDR and BLE Power: 5V/2A Built-in flash light Camera module: OV2640, 200 Mega pixels Schematic Since there is no USB on ESP32, I use